Applications for ultrasonic welding

With the continuous development of science and technology, new welding processes are emerging in an endless stream. The current welding methods can be roughly divided into: electrode arc welding, submerged arc welding, argon arc welding, gas welding, laser welding, two-warrant welding, friction welding, ultrasonic welding, soft brazing, hard brazing. Different materials are suitable for different welding methods. Nowadays, “plastic instead of steel” is rising, engineering plastics have been a large number of applications, PPS materials with its excellent comprehensive properties are widely used in various fields, for PPS material products welding has become the focus of people’s attention, the following follow the domestic engineering plastics manufacturers together to understand part of the welding methods.

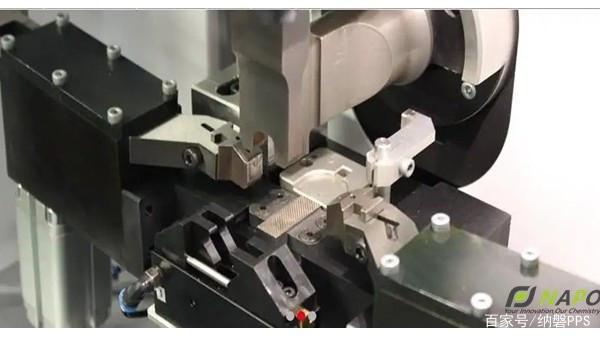

1, ultrasonic welding: the principle of ultrasonic welding is to use high-frequency vibration to quickly rub the contact surface of two objects to fuse. When ultrasonic welding is used for PPS engineering plastic parts, tens of thousands of high-frequency vibrations will be generated per second, when the vibration frequency reaches a certain value, the ultrasonic energy will be turned into thermal energy through energy conversion, so that the contact place will gradually melt, so as to be tightly combined, the advantage of using ultrasonic welding PPS material components is that the interface strength is infinitely close to the strength of raw materials.

2, laser welding: the principle of laser welding is to focus the laser as energy to shoot at the weldment, due to the accumulation of laser energy, thereby generating a lot of heat, melting the contact surface of the weldment, the advantage of using this method is that the welding deformation is small, but the machine is expensive, and a lot of electrical energy is required to drive the machine.

3, friction welding: friction welding is to contact the welded matter together through high-speed rotational friction, resulting in high temperature, so as to locally melt, and then cool the stereotype. The advantages of friction welding are high productivity and simple operation.

In recent years, the field of materials has gradually undergone changes, and materials can now be roughly divided into two categories: metal materials and plastic materials. Many people know more about metals, but they are not very optimistic about plastics, thinking that plastics can only do some low-end products. In fact, plastics also have excellent comprehensive performance, such as the engineering plastic family, PPS materials, PEEK materials, PPA materials in engineering plastics are not inferior to metal materials, and even have more prominent advantages in many aspects.