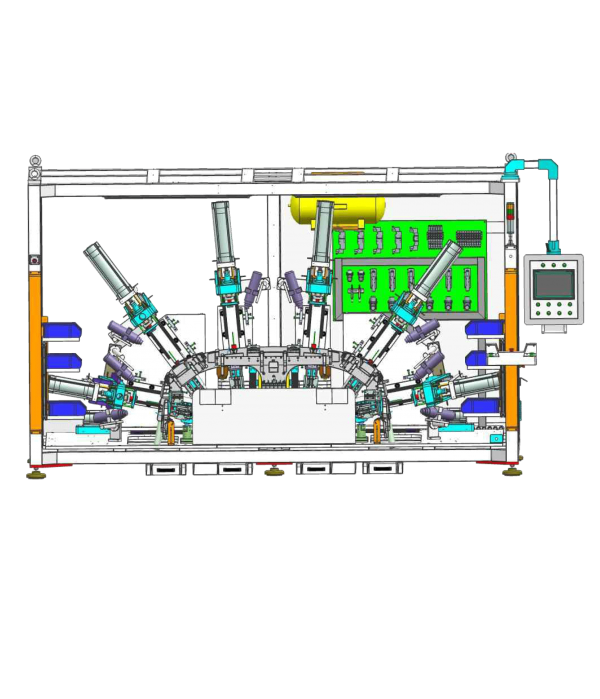

Auto Bumper Ultrasonic Plastic Welding Punching Machine

Punching equipment specially designed for front and rear bumpers of automobiles. It can complete various hole shapes, circles, squares, etc. designed for the bumper; realize the integrated operation of punching and welding.

The equipment adopts multi-station design.

After punching, it runs to the welding radar bracket station;

high-performance sonic piercing welding radar bracket.

+86 1377 68989 23

About WELDHOT

Why WELDHOT?

WELDHOT is widely used in various industries such as automotive lamps, automotive interior and exterior decorations, automotive containers, home appliances, medical care, toys, etc., with customers all over the country and overseas.

WELDHOT equipment for plastic welding solutions is as follows; ultrasonic welding machine, hot plate welding machine, hot riveting welding machine, servo welding machine, hot pressing hemming machine, bumper punching machine, robot flexible welding machine; molds include, hot plate Welding molds, ultrasonic molds, hot riveting molds, vibration friction molds and various tooling.

WELDHOT provides equipment solutions for the entire production line for car lamp manufacturers, including riveting presses, airtight machines, CCD light shapers, pressing machines, dust collectors, work tables and other tooling.

Company Panorama

Production Workshop (Part)

Warehouse

Warehouse

About US

What is the corporate culture

Changzhou WELD Machinery Technology Co. , Ltd.(Short name: Wei Le De Abbreviations:WELD)specializes in the design and development of ultrasound-related equipment. Technical personnel have been in this industry for more than 10 years, the application of ultrasound has unique insights and experience.

Company adhering to the“Technology-driven, quality to survive” business philosophy, “There is no perfect individual, only a perfect team” core values, “Customer is God, tailor-made equipment for customers, serve each god” purpose. We have been moving in this direction, and unremittingly to contact our customers warm service. Customer satisfaction is our unlimited power.

Weldhot Custom process

What the WELDHOT customization process looks like?

WELDHOT in order to let each customer better understand the process of placing an order, specifically provides the following process for reference

STEP01

1.Customers provides drawings;

2.Customers provides the product.

STEP02

1.Design according to drawing;

2.Customer's product are directly trial-produced on the machine.

STEP03

1.Communicate with customer to confirm the design;

2.Send the processed sample to customer for confirmation.

STEP04

After the scheme is confirmed, payment will be made first, and then delivery will be made according to the delivery date confirmation