Portable ultrasonic spot welding machine

The principle of handheld ultrasonic welding machine In the process of ultrasonic welding, the handheld ultrasonic welding machine can increase the vibration amplitude of this high-frequency vibration wave through the amplifier, and then load it into the mold, through the upper mold, the enhanced high-frequency vibration wave acts on the product, so that the instantaneous high-frequency vibration between the products can not produce high heat, so as to achieve the purpose of product welding together.

The handheld ultrasonic welding machine is composed of a high-frequency current converter, a piezoelectric converter, an amplitude modulator, an electrode arm or a sonic rod.

- High frequency current converter

The main function of the high-frequency current converter is to convert the input low-frequency current into the output high-frequency current, and its frequency range is the same as the ultrasonic frequency range, and the output frequency of 20khz is more commonly used in ultrasonic welding.

- Piezoelectric converter

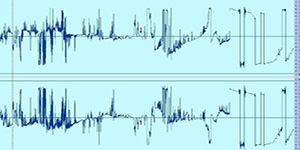

The role of a piezoelectric converter is to convert electrical energy into mechanical vibration energy while the frequency remains constant. Usually done by a piezoelectric or frequency converter, it is the use of asymmetrical crystals, such as natural quartz wafers, synthetic lithium titanate or barium wafers, etc., in the alternating electric field will occur with the change of current frequency and the same frequency of mechanical deformation or size contraction, also known as piezoelectric effect. The piezoelectric effect of these chips can be used to convert high-frequency electrical energy into ultrasonic energy.

- Amplitude modulator

The expansion or contraction of the piezoelectric material under the action of AC voltage produces high-frequency vibration, but the degree of this vibration is not large, about (0.01-0.02mm). This is obviously not enough to produce a good weld, so use a part of the called amplitude adjuster on a handheld ultrasonic welding machine to increase the amplitude. This is a half-wave aluminum or titanium resonator.

- Electrode arm or sonic rod

Electrode arm or sonic rod, also known as ultrasonic mold, is a tool that transmits energy to the plastic product to be welded, usually made of alloys such as aluminum and titanium. Its function is to convey high-frequency vibration and pressure to the welding part of the part with the amplitude of the electrode arm end increases, and the typical vibration amplitude range is (0.05-0.12)mm. The design of the electrode arm is a complex matter, in addition to the shape to match the contour of the product to be welded, but also in the process of welding the product should also ensure that its frequency matches the handheld ultrasonic welding machine. In order to ensure the smooth progress of the welding process, the electrode arm is generally designed and manufactured by the handheld ultrasonic welding machine manufacturer or acoustic research institution.

Small size, simple operation, fast cleaning; The use of module integrated circuit, strong power output;

Built-in automatic protection circuit, safe to use, stable and reliable work. The welding surface is firm, high strength, beautiful and environmentally friendly.

According to the riveting size of the product to be welded and the welding requirements, replace different ultrasonic welding heads, which is fast and convenient, suitable for plastic welding of automotive interior parts.