Flexible car bumper radar bracket ultrasonic punching machine

First. bumper punching welding machine Introduction: This equipment adopts the use of high-strength steel as the frame, 4-6 ultrasonic welding heads at the same time up pressure welding, single welding head split control, a single welding head can be adjusted position (three-axis adjustment), the use of welding tooling slide structure, cylinder from the release area to the welding area. The limit screw can adjust the height of the upper die, PLC man-machine interface control, the use of side pull structure for easy commissioning and installation, high accuracy. The whole machine is convenient for debugging and stable performance. The equipment push mechanism can be divided into manual and automatic operation, manual for single action, mainly used for mechanism and mold debugging. Enter the main operation screen on the PLC computer touch screen, and set the welding time, curing time and delay time according to the welding requirements of the workpiece. The computer touch screen is automatically determined, the movable door (proximity switch indicator is on) or the safety light grid is closed, and the start switch (blue) button is pressed at the same time, and the process is fully automatically controlled by PLC control. Start the switch upper die to press down the workpiece. Production is carried out automatically, and the automatic control system uses a programmable controller (PLC) to control the continuous movement of the cylinder. Easy operation, reliable performance and compact size improve production efficiency and quality.

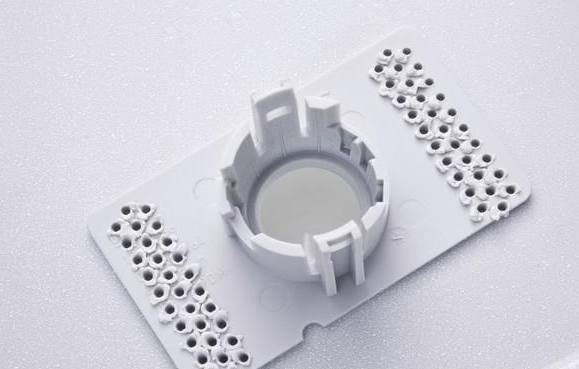

Second, the application range of bumper punching welding machine: suitable for car front and rear bumper radar mounting hole punching cutting, turn signal hole punching cutting, bracket welding, etc.

Third, the main features of the car bumper punching machine:

Ultrasonic punching and cutting process, fast speed, no burr. Radar hole punching and cutting and radar bracket welding are automatically completed to ensure product quality The internal space of the equipment is large, and the action stroke is also flexibly adjusted, suitable for the bumper of each model. Each system is independently controlled, easy and fast to adjust, and ensure the product qualification rate. The equipment is designed with multiple safety protection sensors to ensure the safety of man and machine. The product surface protection device is used to ensure that there are no scars on the surface of the product being punched and cut.

Fourth, the main technical parameters of the car bumper punching machine:

1, the power consumption of the whole machine: ≤5.5KW;

2, a single set of ultrasonic output power: 1800W;

3. Working frequency: 20KHz;

4. Moving stroke of die and bottom die: 300/350 mm;

5. Punching time: ≤ 20 seconds (the time of loading and unloading products is also counted);

6. Working power supply: AC220V/50Hz ±10%;

7. Working air pressure: ≥0.5Mpa.

Fifth, flexible bumper punching and welding machine

Robot flexible car bumper ultrasonic punching machine, the main features of the ultrasonic punching and cutting process, fast speed, no burr. Radar hole punching and cutting and radar bracket welding are automatically completed to ensure that the internal space of the product quality equipment is large, and the action stroke is also flexibly adjusted, suitable for the bumper of each model. Each system is independently controlled, easy and fast to adjust, and ensure the product qualification rate. The equipment is designed with multiple safety protection sensors to ensure the safety of man and machine. The product surface protection device is used to ensure that there are no scars on the surface of the product being punched and cut. The main functions of the auto bumper ultrasonic punching machine are: 1. For the car bumper, the front insurance, the rear insurance, the radar bracket, the fog lamp bracket, the headlight cleaning bracket punching and welding 2. The punching accuracy can reach 0.1mm, the inverted R angle 3. The punching unit adopts hydraulic cylinder or pneumatic hydraulic booster cylinder or cylinder drive 4, and the frequency is generally 35KHZ40KHZ