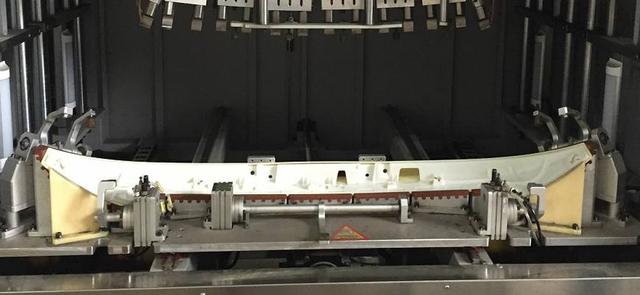

Automotive spoiler welding machine belongs to an ultrasonic multi-head welding machine, the use of ultrasonic puncture welding, the two ABS injection molded parts without any medium directly welded together, the welding process is stable, the degree of firmness up to 70% of the body strength, the cost is better than the effect of the dispenser on the market.

Working principle:

Automotive spoiler is often called automotive tail wing plate, car tail wing plate is composed of two to three parts of welding, in order to achieve aesthetics, ultrasonic spot welding is usually used. Auto spoiler welding machine, by a number of sets of 35k ultrasonic system with two sets of ultrasonic handles, tailor-made soldering station to facilitate a variety of automobile manufacturers tail wing anastomosis welding, to achieve beautiful, efficient and firm purposes.

Automotive spoiler tail puncture ultrasonic multi-station automatic welding machine is a multi-station ultrasonic welding non-standard equipment, multi-station movement is to facilitate the distribution of solder joints when welding the upper and lower parts of the tail wing, because the structural shape of the tail wing is more diverse, so it is necessary to inject molding the upper and lower parts, through secondary welding to complete the assembly, the original assembly process from glue bonding and nut fixing to the current ultrasonic puncture welding, in terms of environmental protection and cost savings have been greatly improved.The advantage of using ultrasonic welding is that the welding speed is fast, the welding fastness is high, and the welding of different tail fin assembly welding can be completed simultaneously on one piece of equipment by changing the welding tooling. The ultrasonic system of this equipment adopts imported system, so the ultrasonic output stability is high, the failure rate is low, and the ultrasonic welding head is made of imported alloy material, which greatly increases the service life of the welding head. Generally, the welding beat of a tail wing can be completed between 55 and 80S, and the production cycle of different tail spoilers is different according to the number of solder joints.

Solving problems for customers is our eternal pursuit!

WELDHOT Brain Writing