Plastic hot riveting machine, ultrasonic plastic hot riveting machine, hot melt plastic hot riveting machine, rotary plastic hot riveting machine, plastic hot riveting equipment, hot melt plastic riveting machine, plastic hot riveting machine, plastic hot riveting machine, hot melt hot riveting machine, plastic column hot riveting machine, plastic protrusion hot riveting machine, ultrasonic plastic hot riveting machine, plastic riveting welder – ultrasonic plastic welding machine are mainly used for the secondary connection of thermoplastics, Compared with other traditional processes (such as gluing, ironing or screw fastening), it has significant advantages such as high production efficiency, good welding quality, environmental protection and energy saving. Ultrasonic plastic hot riveters are widely used in medical appliances, packaging, auto parts, fishing gear and other industries, such as disposable infusion filters, plasma separation cups of blood plastic hot riveters, self sealing bags, plastic wine bottle covers, dishwasher water wheels, plastic plastic hot riveter toys, lamps, plastic false bait, welding of charger shell and mobile phone sling, welding of primary lighter shell, etc.

Product design:

1. The electric control part adopts man-machine interface and PLC control. ①. The plastic hot riveter is designed with double button startup to improve practical safety. The emergency stop protection device ensures production safety. ②. Adopt engineering design, reasonable structure and safe use. ③This machine has beautiful appearance design Specifications: Power: 1800W-4200W Scope of application: for some plastic products that cannot be hot riveted on the front or are difficult to be hot riveted on the front

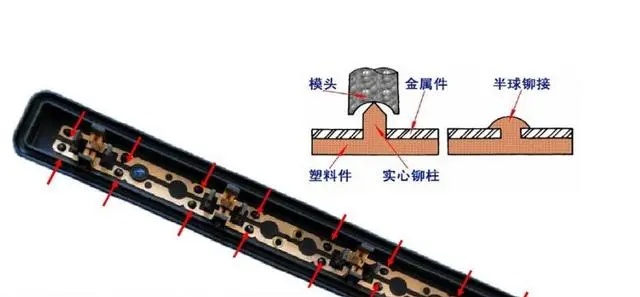

Plastic hot riveting machine is to use a hot melt plastic part to reserve the inherent plastic rivet column, rib wing and fold edge, and then use the cold rivet head to compact, cool, reshape and clamp after controlled hot melting and softening. The special shape rivet head can be used to realize the countersunk hot riveting (flat hot riveting) of plastic rivet column, the hot riveting of hemispherical plastic hot riveting machine, the hot riveting of arc flanging, the rib shaped hot riveting, mechanical forging and pressing, the folding inlaying and covering, etc, Connecting machine for assembling different material machines, plastic hot riveting machines and riveting machines.

The plastic hot riveting machine has won good market recognition and very good reputation.

The plastic riveting welding machine is not easy to embrittle, beautiful, firm, and sealed, so as to achieve the optimal design of the structure, the most perfect combination, and has no noise, no pollution, suitable for rapid production environment, to ensure that the product quality is long-term stable, reliable, and beautiful. The plastic hot riveting machine has the advantages of energy conservation, high efficiency, high cost performance.

Scope of application of plastic riveting welder: hot riveting of auto parts, hot riveting of various plastic products, copper nails, screw embedding, plastic riveting forming, mobile phone antenna, mobile phone shell, connector, MP3, computer interior decoration,earphones, toys,etc

WELDHOT Brain Writing