In car magazines and car guides, you often see “A-pillar”, “B-pillar” and “C-pillar”. The A-pillar refers to: the column between the windshield and the left and right front doors. The A-pillar is between the engine compartment and the cockpit, above the left and right mirrors, which will block part of your turning horizon, especially the left turn, so it is more discussed. The A-pillar, B-pillar and C-pillar are the main parts that support the structural strength of the vehicle.

Automotive A-pillar welding is a welding method using hot melt or ultrasonic process, mainly the welding (riveting) of plastic pillars, the edging of A-pillars, etc.

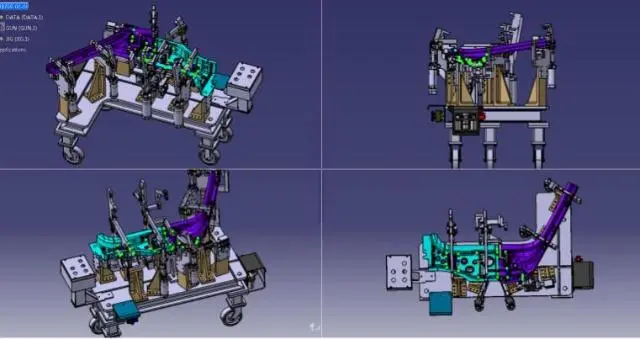

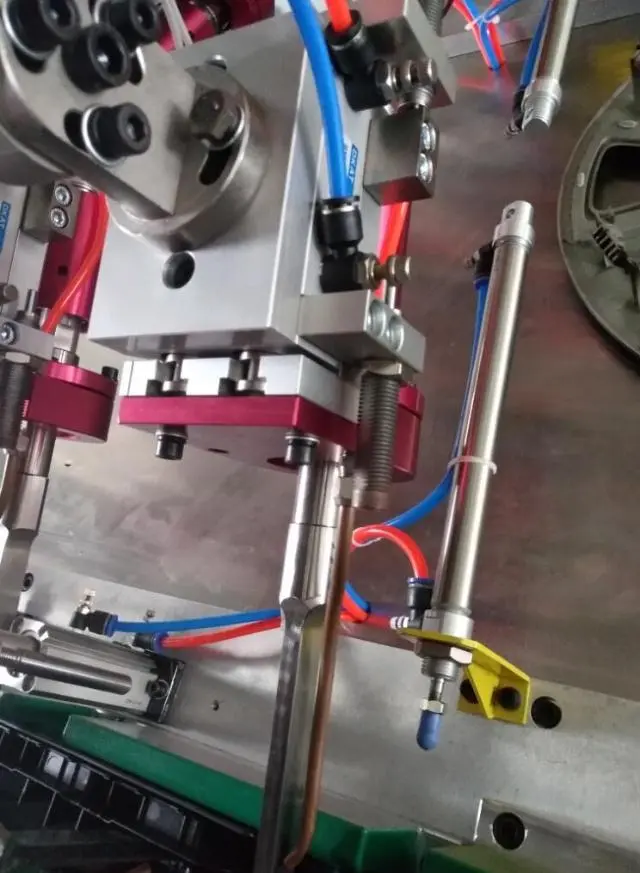

The automobile A-pillar plastic parts welding machine is a multi-head non-standard ultrasonic equipment, which is designed and processed according to the welding point of the A-pillar. The left and right parts of the A-pillar of the car are welded through multiple sets of ultrasonic systems, which can reduce the production time. Increase production capacity. The angle, frequency, shape design are all to be taken into account. The welding bottom mold of the product adopts surface spraying treatment, which can avoid scratches on the surface of the product during welding and improve the welding quality. The machine adopts PLC control, all kinds of welding parameters can be freely adjusted on the touch screen, which is convenient for the welding of different products, the machine is fully automatic welding control, workers only need to put and pick up parts, which reduces the difficulty of operation.

WELDHOT Brain Writing

Great article! I really appreciate the clear and detailed insights you’ve provided on this topic. It’s always refreshing to read content that breaks things down so well, making it easy for readers to grasp even complex ideas. I also found the practical tips you’ve shared to be very helpful. Looking forward to more informative posts like this! Keep up the good work!