Automotive interior plastic column hot melt welding machine

Equipment technology and working principle: hot melt welding of thermoplastic materials is the use of electric heating plastic welding machine melting principle, accurate control of temperature changes, and equipped with perfect mechanical devices to achieve perfect riveting. It has excellent results for workpieces with large and complex workpiece areas and high welding requirements. Frame: steel, castings and bolts and welded connection structures. Mold: using positioning structure, installation and debugging is convenient, fast, accurate positioning, composed of several hot plates hot mold. A variety of plastic parts can be used.

Welding body: the welding part of the whole machine, the welding body can independently complete the welding of each single welding part, and then with the help of the equipment control system to accurately move the welding body to each part to be welded to complete the welding of the overall plastic parts. The welding body is composed of the following parts.

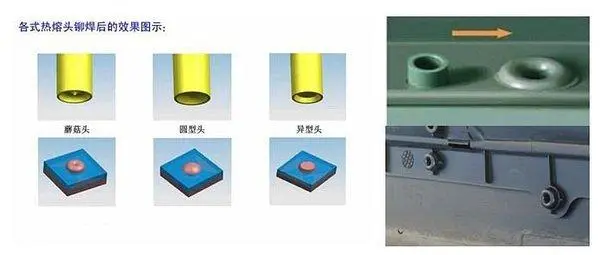

Hot melt riveting 1, tooling template: used for the fixing of plastic parts (including assembly parts), the lower cold mold is made of integrated whole face, the function is to firmly fix the plastic parts in the mold cavity, complete the entire welding process. Installed on the welding main workbench, with the welding bottom mold tooling overall replacement, a single door panel a tooling template, in the work can be quickly replaced as needed. 2. Upper hot mold: used for hot melt of upper plastic parts, installed in the middle of the welding body, hot melt is completed by contact type on the upper plastic parts, moves with the welding body, and can move up and down in the welding body. 3. Action system inside the welding body: the upper hot mold up and down welding action and the bottom mold tooling clamping or demolding are two parts, and the welding action accurately and quickly completes each welding of the workpiece through pneumatic components and linear guide rods; The bottom mold is also a flexible and accurate completion of the welding body in the welding through the pneumatic system. Hot melt molds

Temperature control system: The temperature of the hot mold can be flexibly adjusted according to the needs of the immovable plastic parts. And the function of controlling the temperature of the hot mold and displaying it separately to ensure the qualified rate of the welded product. The action control system of the whole machine: the action control part of the whole machine can accurately and flexibly move the welding body to the required welding part according to the needs of the workpiece, for different products, our equipment has the ability to design a rapid mold change structure, which is convenient for the mass production of products. It is especially useful for a wide range of product specifications

WELDHOT Brain Writing