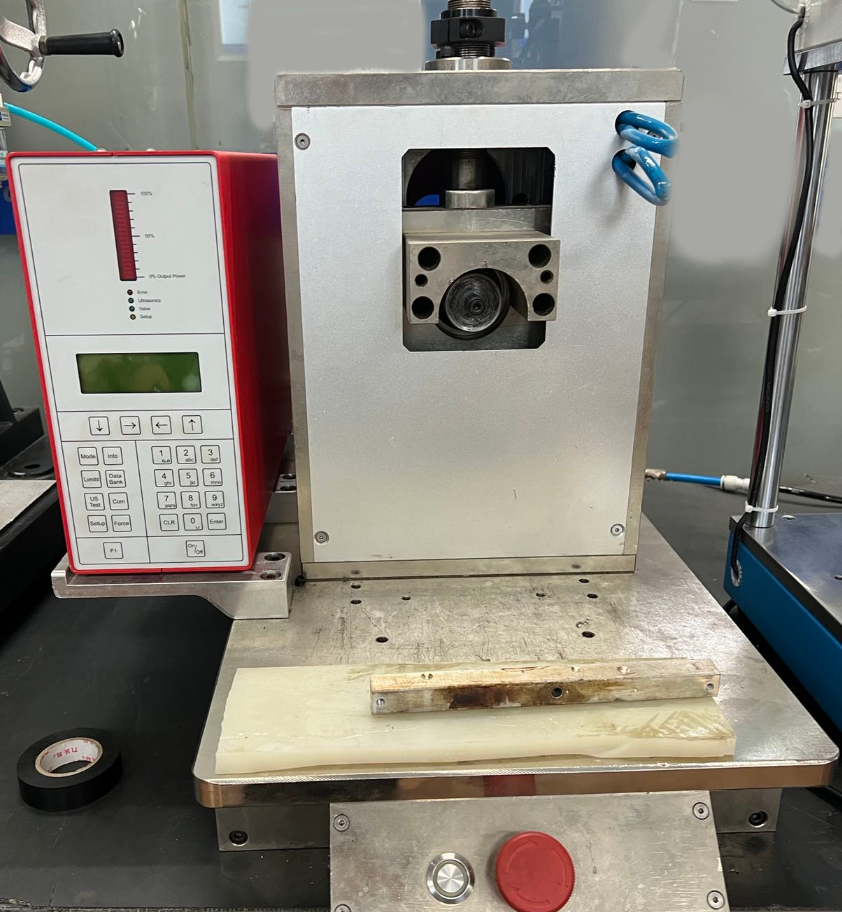

Ultrasonic metal welding machine

Ultrasonic metal welding was discovered by accident in the 1830s. It is similar to friction welding, but there is a difference, ultrasonic welding time is very short, the temperature is lower than recrystallization; It is also different from pressure welding because the applied static pressure is much smaller than pressure welding. It is generally believed that in the initial stage of the ultrasonic welding process, the tangential vibration goes out of the oxide on the surface of the metal, and the protruding part of the rough surface produces repeated micro-welding and destruction of the process and increases the contact area, while increasing the temperature of the welding area, and producing plastic deformation at the interface of the weldment. In this way, under the action of contact pressure, when they are close to each other to the distance at which the gravitational force of the atom can act, a solder joint is formed. The welding time is too long, or the ultrasonic amplitude is too large, so that the welding strength is reduced or even destroyed.

The advantages of ultrasonic metal welding are:

1: Fast welding speed;

2: High welding strength;

3: Less energy consumption required;

4:: The welding process is convenient and there is no pollution, and no other auxiliary equipment is required;

5: Welding equipment is small in size and easy to use.

Disadvantages of ultrasonic metal welding:

1: Only a small amount of metal such as aluminum, magnesium and copper can be welded;

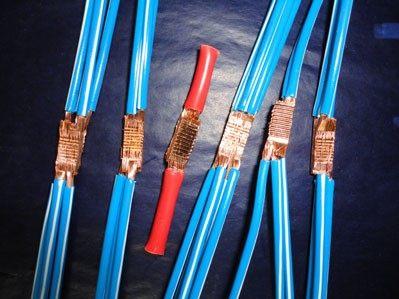

2: Only metal sheets can be welded, metal thin wires;

3: The shape of the welding material is required to be high.

Ultrasonic metal welding is a special method of connecting the same metal or a different metal by using the mechanical vibration energy of the ultrasonic frequency. When the metal is welded to ultrasonically, neither current is transmitted to the workpiece nor a high-temperature heat source is applied to the workpiece, but under static pressure, the mechanical energy is converted into internal energy, deformation energy and limited temperature rise. Solid-phase welding occurs when the two base materials reach the recrystallization temperature. Therefore, it effectively overcomes the phenomena of splashing and oxidation caused by resistance welding. Ultrasonic metal welding machine can perform single-point welding, multi-point welding and short strip welding of microfilament or flake materials of non-ferrous metals such as copper, silver, aluminum, nickel and so on. It can be widely used in the welding of thyristor leads, fuse pieces, electrical leads, lithium battery pole pieces, and pole ears.

Ultrasonic metal welding uses high-frequency vibration waves to transmit to the metal surface to be welded, and in the case of pressurization, the two metal surfaces rub against each other to form a fusion between the molecular layers.

Solving problems for customers is our eternal pursuit!

WELDHOT Brain Writing

Nice post. I learn something new and challenging on sites I stumbleupon everyday. Its always interesting to read content from other writers and practice a little something from their sites.