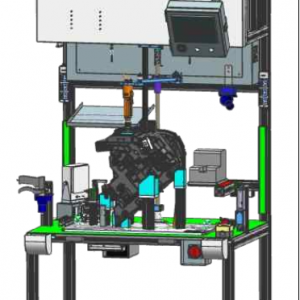

15 khz ultrasonic plastic welding machine 15 khz ultrasonic plastic welding machine is through a transistor function equipment to 15 khz high-frequency electrical energy into ultrasonic mechanical vibration energy, the pressure regulator transmits the converted mechanical energy to the welding head of the Ultrasonic welding machine. The welding head is an acoustic device that transmits the mechanical vibration energy directly to the product to be pressed. The vibration transmits the heat energy to the adhesive surface by the vibration friction of the welding work piece, which causes the plastic to melt, the vibration stops when the molten material reaches its interface, giving it a certain amount of pressure. When the vibration stops, the temperature drops rapidly, because the plastic’s poor thermal conductivity cools and solidifies rapidly locally, where the plastic molecules move into the mold voids to achieve the effect of welding, the whole cycle is usually completed in less than a second. The application of ultrasonic welding of thermoplastic parts can use welding, riveting, forming welding or spot welding and other methods. The Ultrasonic welding can be operated independently or in an automated production environment.

Ultrasonic Welding Machine

15KC Ultrasonic Welding

Machine (High Power)

Function & Specification

frequency: 15-20KHZ

power: 4200-6000W

air pressure: 0.1-1.0MPA

Voltage: AC220V

Welding head stroke: 100MM

Dimensions: 750*800*2000MM

output time: 0.01S-9.99S

Intelligent management: Amplitude, Quality,

Safety

Body weight: 350KG

Operating mode: button, external control

Circuit system: Digital intelligent automatic

frequency tracking

system language: Chinese-English

Operation interface: 4.3 touch inside

Features: Welding records and statistics

-300x300.png)