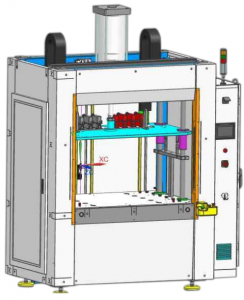

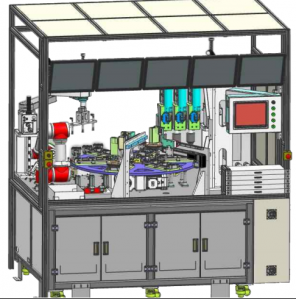

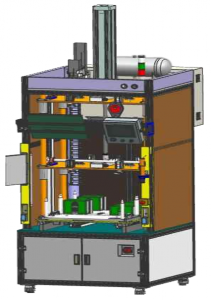

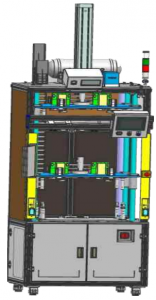

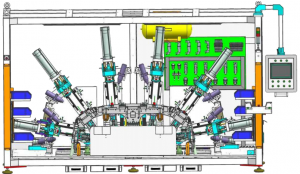

Airtight Machine

Introduction:

It is used for automobile headlights, taillights, air

tightness testing; it can be equipped with various

brands of air tightness testers, Wan testers,

COSMO, etc. according to customer

requirements; the equipment is equipped with

real-time monitoring and alarm function of

intake pressure; Dotting and other actions after

the airtightness is completed.

-251x300.png)

-251x300.png)